A well-functioning grease trap is an essential piece of equipment for any establishment that deals with food preparation, especially commercial kitchens. But how exactly does a grease trap work? This seemingly simple device plays a crucial role in preventing costly backups, protecting the environment, and ensuring compliance with regulations. Waste Solutions of Iowa, serving Ankeny, Des Moines, Waukee, West Des Moines, IA, and surrounding areas, is here to break down the science behind grease traps and explain the benefits of proper maintenance.

How does a grease trap work?

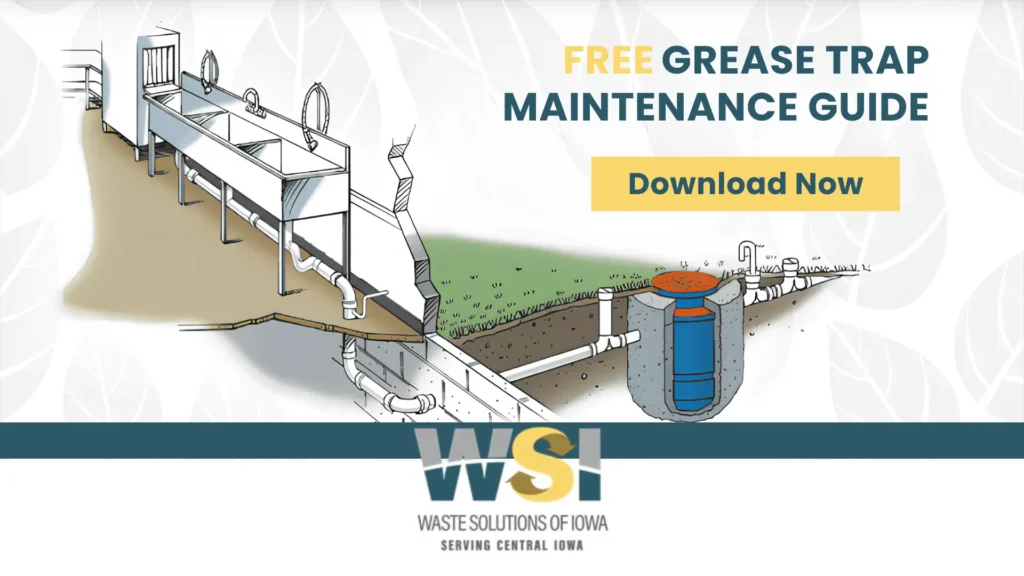

Grease traps operate on a deceptively simple principle: density separation. Here’s a breakdown of the process:

1. Explain the science of separation

Fats, oils, and grease, collectively known as FOG, are all lighter than water. This density science helps the trap distinguish these valuables from the waterway.

2. Describe the flow process

According to the top commercial kitchen plumbing experts in Des Moines, wastewater containing FOG enters the grease trap through an inlet pipe. The flow rate is crucial – a slow and steady flow allows for optimal separation.

3. Three-layer separation

Within the trap, the wastewater stratifies into three distinct layers:

- Top layer: FOG, being lighter than water, rises and forms a layer on the trap’s surface.

- Middle layer: Lukewarm wastewater (with some residual FOG) resides here.

- Bottom layer: The solid particles in the food and other waste material, which are larger in size and weight compared to them, will, due to gravity, come to rest at the bottom of the trap.

4. Baffles and their role

The design of grease traps usually, but not necessarily, includes baffles to be installed. Baffles are plates or walls that hinder the flow rate and movement of wastewater. This helps to create a “calming zone” in the grease trap, which, in turn, would help separate greater amounts of FOG simply because the baffle lowers the velocity of the wastewater, thus increasing the time for FOG to float.

5. Outlet Placement

Located strategically under the FOG and middle water layer, the outlet pipe allows the treated wastewater to exit the trap and proceed on its way toward the sewer system.

Benefits of Using Grease Traps

The benefits of employing grease traps in commercial kitchens are numerous:

1. Prevent sewer blockages:

According to the leading grease trap cleaning and maintenance experts in West Des Moines, IA, when grease builds up, the FOG within it is a definite recipe for disaster for the sewer lines. Grease traps ensure effective FOG capture before discharging into the sewer system, thus averting costly and disruptive blockages.

2. Protect the environment:

Uncontrolled FOG(Fats, Oils, and Grease) discharge to aquatic life can be extremely hazardous. Grease traps are important in preventing the entry of FOG into our waterways, making the environment safe for the future.

3. Maintain plumbing health:

Top commercial kitchen plumbing contractors in Waukee reveal that FOG accumulation in your plumbing system will result in clogging, leaking, and possibly even corrosion. The grease traps are proactive and will keep your plumbing working as it should without any hassles.

4. Compliance with regulations:

In the United States, most cities within states have regulations that require grease traps to be used and regularly maintained. Without compliance, unnecessary fines and penalties can spiral. Grease traps help protect your establishment from this.

5. Improved Kitchen Efficiency:

Clogged drains and malfunctioning plumbing due to FOG buildup can significantly slow down operations in a commercial kitchen. Grease traps increase kitchen efficiency by maintaining the wastewater flow rate within the area.

6. Reduced Fire Risk:

Grease can accumulate and become a fire hazard over time. According to the top licensed grease trap cleaning and maintenance professionals in Ankeny, the grease traps hold this material back, mainly from the rest of the drainage system, thereby reducing the kind of subdued material that would have helped in combustion and making it less likely for a fire to break out.

Types of Grease Traps

There are two major types of grease traps that find application in commercial kitchens:

1. Gravity grease traps:

This is the most common grease trap type; it purely works on gravity to separate FOG. It’s usually located underground or under the floor and requires common grease trap services, including routine cleaning, pumping, and maintenance, provided by an approved operator—a service Waste Solutions of Iowa proudly provides in Ankeny, Des Moines, Waukee, and nearby locations.

2. Automated grease traps:

These advanced traps use skimmers, timed pumps, or other mechanisms to remove the FOGs(Fats, Oils, and Grease) automatically. While offering a high level of convenience, automatic grease traps require more maintenance and sometimes are more expensive than gravity traps.

Maintaining Your Grease Trap

Following are some important practices that help in maintaining your grease trap and keeping it optimal:

1. Install Grease Screens:

Top grease trap cleaning experts in West Des Moines, WA, reveal that fine mesh screens over the drain catch large food scraps and FOGs before they enter the grease trap, thereby reducing the system’s total load.

2. Manage Cooking Temperatures:

FOG is released in great amounts from overheated cooking oil. Keeping proper temperatures while cooking is good for quality, but it also helps reduce the formation of FOGs.

3. Use Grease Trap Enzymes:

These biological additives can help break down FOG(Fats, Oils, and Grease) within the grease trap, reducing the need for pumping and maintenance frequency.

Note: Before using enzymes, consult a licensed grease trap professional like Waste Solutions of Iowa, as some can be incompatible with certain trap types.

4. Regular Inspections:

Schedule periodic grease trap inspections from a properly licensed or trained professional, such as Waste Solutions of Iowa, to inspect the health of your grease trap and point out any potential problems.

How Often Should You Clean Your Grease Trap?

How often you clean your grease trap is determined by a few factors, including:

1. The size and volume of your establishment:

According to the top commercial kitchen plumbing contractors in Ankeny, larger kitchens producing more FOG must be cleaned more frequently.

2. The type of food you prepare:

Some foods, mainly those with high greasy fried foods, produce more FOG.

3. Local regulations:

Leading grease trap cleaning experts in Waukee also reveal that some municipalities may have specific requirements for grease trap cleaning frequency.

The 25% rule serves as a helpful guideline for determining grease trap cleaning frequency. This rule states that grease trap cleaning should be performed when the FOG layer reaches 25% of the trap’s total capacity.

However, relying solely on the 25% rule might not be sufficient. The most proper approach would be to have regular inspections by Waste Solutions of Iowa or some other licensed on-site septic professional who can further assess your particular needs. Our team can consider variables like those explained above and recommend a custom cleaning schedule to ensure peak performance and compliance with local regulations.

What exactly is the 25% Rule for Grease Traps?

The 25% rule is a widely used guideline established by some regulatory agencies in the US. According to this rule, grease trap cleaning is required when the thickness of the floating layer of FOG reaches 25% of the grease trap capacity. This prevents overflow of the FOG layer overfilling into the sewer system and prevents the occurrence of blockages and other environmental problems.

However, the ideal cleaning frequency for your grease trap may vary Depending on the size and volume of your business, the kind of food prepared, and even local regulations.

Contact Us Today for a Free Grease Trap Service Quote!

At Waste Solutions of Iowa, we understand the importance of maintaining a functional grease trap for your commercial kitchen. Our team of licensed professionals is equipped to handle all your grease trap functions, from routine cleaning and maintenance to expert advice and compliance assistance. We proudly serve the areas of Ankeny, Des Moines, Waukee, West Des Moines, and nearby IA areas.

Call Waste Solutions of Iowa today for a free quote for grease trap service! We will be more than happy to discuss your specific needs and provide you with the best solution for your business. We offer unparalleled service at very competitive prices, so you can feel satisfied knowing your grease trap interceptor is in good hands.

Don’t let grease trap failures bring your operation down. Proactive grease trap maintenance prevents costly, unscheduled downtime and secures your kitchen’s continuous smooth running. Team up with Waste Solutions of Iowa and have peace of mind knowing your grease trap will function properly and your business complies with local regulations.

Contact us at (515) 750-2349 to schedule an appointment with our team today.