GREASE TRAP CLEANING SERVICE

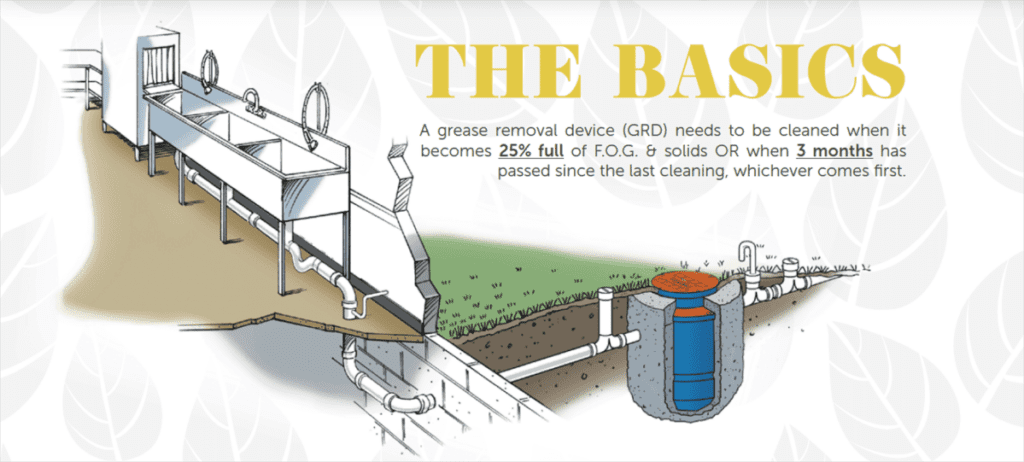

Iowa law requires grease traps to be pumped and cleaned at least every three months. WSI offers a preventative-maintenance service program that allows you peace of mind. Our highly knowledgeable grease service staff members will monitor your usage with every visit – making sure you stay compliant and one step ahead of any issues that may arise.

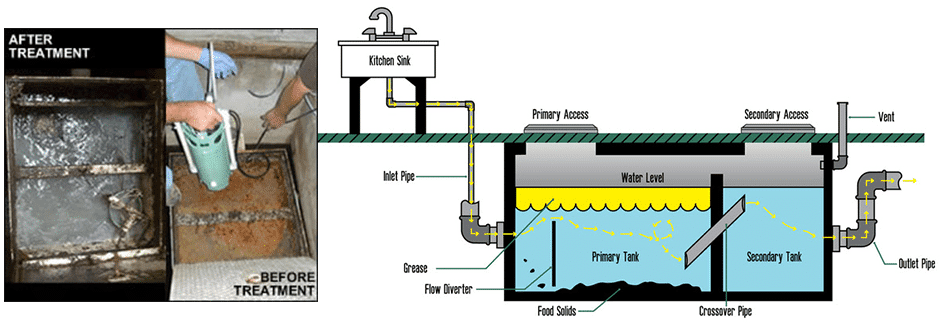

Grease Trap Cleaning goes beyond simply removing grease from a food service trap. By getting rid of residual grease from trap walls and deep cleaning all parts of the trap once the FOG is gone, we’re helping your business avoid downtime for a grease trap issue. Waste Solutions of Iowa uses up-to-date methods and techniques to provide quality grease trap cleaning and disposal service.

What are grease traps? Grease traps, also known as interceptors, grease interceptors, grease wastewater separators, and grease wastewater treatment systems are used to collect food, fats, and oils (FOGs) from the drainage systems of commercial kitchens (like restaurants). A dirty or poorly maintained grease trap can lead to overflows and backups that cause serious problems including flooding and sewer back-ups. That’s why it’s important to keep your grease traps clean and preventative-maintenance programs will help you do just that!

In Iowa, state law requires that traps be cleaned at least every three months, but more frequent cleanings will be required if an influx of wastewater is experienced or if a lot of fat and debris (FOG) has been building up in your system. Waste Solutions of Iowa is your local company and resource to help you understand how often your traps will need to be cleaned based on your usage. The bottom line: don't wait too long between cleanings, but you don't have to stress out about your grease trap either with a consistent cleaning schedule and maintenance plan with WSI.

When most people think of grease traps, they only consider cleaning. After all, a clogged trap means wasted money, down time and a big mess. Grease can also lead to clogged drain lines due to infrequent grease trap cleaning. But there’s a lot more to taking care of your grease trap than simply removing grease. A preventative maintenance program is key in keeping your trap running properly —without breaking your budget. There are several aspects to pay attention to when it comes to preventative maintenance: our team at WSI will get rid of residual grease from trap walls and deep clean all parts of the trap once the FOG is gone. We work to proactively help your business avoid downtime for a grease trap issue. Waste Solutions of Iowa uses up-to-date methods and techniques to provide quality grease trap cleaning and disposal service.

- Ankeny

- Des Moines

- Waukee

- West Des Moines IA

Interior Grease Service

Our basic, 30-minute grease trap service that requires no specialized attachments or machinery.

Interior Grease Service

Our basic, 30-minute grease trap service that requires no specialized attachments or machinery.

*See our Service Area Map for details.*

Grease Interceptor Service

It’s important to have a regular grease interceptor maintenance plan. WSI provides regular grease interceptor cleaning services in Iowa and we have years of experience with different interceptors and disposal methods. Our team will work closely with you to ensure that your interceptor stays functional for years to come.

Interceptor Grease Service

Our grease interceptor services are done by a larger truck. Interceptors are located outside and are typically done late in the evening or early in the morning

Grease Trap or Grease Interceptor – What’s the Difference?

A grease trap is sometimes called a grease interceptor. They both perform the same task — prevent Fats, Oils & Grease (FOG) from entering the plumbing and sewer collection system — but grease traps and grease interceptors differ in one key area – the flow rate of wastewater. Grease traps can handle less than 50 gallons of wastewater per minute while grease interceptors can handle more than 50 gallons per minute. If a restaurant’s wastewater exceeds 50 gallons per minute, it may need to use an interceptor instead of a trap. An interceptor also has overflow protection, which is critical for commercial kitchens where drainage is often blocked by pots or pans in sinks and food service lines that can quickly clog up drains. This can cause dangerous backups; an interceptor works to separate out solids before they reach your plumbing pipes and sewage system so you won’t have any issues with overflows causing damage or emergency calls to local plumbers which can be very expensive! Finally, the other difference is installation location. Grease traps are usually installed underneath a commercial sink, while a grease interceptor is generally located underground, outside the building.